IIPFM展商山东旭日东环保股份有限公司(以下简称旭日东)专注于纸浆模塑制浆设备及污水处理设备的生产和研发。

纸浆模塑制浆设备

XuRiDong is one of the earliest manufacturers of pulp molding equipment in China, and it is also the company that established the research institute earlier in the paper molding industry. It mainly produces pulp equipment, pulp molding equipment, clean pulp equipment, environmental protection equipment and garbage disposal equipment in five categories, with more than 60 series and more than 200 kinds of products, and 36 kinds of products have obtained national patents.

01

双盘磨浆机

double disc refiner

双盘磨浆机是引进国外转让技术,浆料由两根进浆管进入磨区中心,在离心力和进浆压力的作用下通过磨区,经过磨区内齿盘的搓揉挤压完成打浆过程。适合化学木浆、机械浆、废纸浆的连续打浆,适宜浆料浓度2-5%,配有自动控制系统,实现恒能耗或恒功率打浆,打浆效果稳定。

The double disc refiner is an imported technology transferred from abroad. The pulp enters the center of the grinding zone through two inlet pipes, and passes through the grinding zone under the action of centrifugal force and inlet pressure. The pulp is then kneaded and squeezed by the toothed disc in the grinding zone to complete the pulping process. Suitable for continuous pulping of chemical wood pulp, mechanical pulp, and waste pulp, with a suitable pulp concentration of 2-5%, equipped with an automatic control system to achieve constant energy consumption or constant power pulping, and stable pulping effect.

●工作原理 working principle

双盘磨浆机由磨浆室、传动机构、底座、电动机等组成。磨浆室由固定在机壳和移动座上的两个固定磨片与安装在转动盘上的两个转动磨片,形成两个磨区。通过调换不同齿形的磨片,以适应各种浆料的打浆要求。

它具有占地面积小,生产效率高、电耗低、操作方便、维修容易等特点。适用于多种浆料的成浆打浆,是目前较为理想的成浆打浆设备。根据工艺要求,本机可单台使用,也可多台串联使用。

It has the characteristics of small footprint, high production efficiency, low power consumption, easy operation, and easy maintenance. Suitable for pulping and pulping of various pulp materials, it is currently an ideal pulping and pulping equipment. According to the process requirements, this machine can be used as a single unit or in series with multiple units.

02

高低浓除砂器

high consistency cleaner

●产品介绍 instruction

该除渣器由耐磨材料制成的进口头、双锥体、气动控制部分组成。纸浆在一定压力下沿切线方向进入除渣器,利用进出口压差作动力,使纸浆沿锥体作螺旋运动并产生离心力,纸浆中的重杂质在离心力作用下,被抛向上锥体内表面,并靠重力作用向下运动,良浆由中间的上出口排出。重杂质及部分纤维下沉至下锥体,在冲洗水作用下进行反冲洗涤,使纤维上浮至上锥体沿良浆方向排除,,重杂质经下锥体球阀下沉至由铸铁制成的沉渣罐内。沉渣罐上设有给水口、排气口、排渣门、视窗,供清洗、排气、观察及排渣用。在进口头上还装有进出口压力指示表,供运行中观察进浆压力及进出口压差。

03

高频疏解机

deflaker

●产品介绍 instruction

XuRiDong has introduced Japanese technology to develop the XDLC series high-frequency, which integrates pulping, dewatering, and sand removal, and has the function of one machine with multiple uses. This machine is capable of completely dissociating various fibers such as grass fibers, recycled fibers from waste paper, glass fibers, ceramic fibers, and asbestos fibers, especially in processing high moisture strength waste paper, with excellent results and very high processing efficiency. Such as processing waste paper of RMB, invoice, military map, tableware, electronic packaging, stainless steel protective film, etc., wet strength paper with added wet strength agents, oil proof agents, and waterproof agents. Simultaneously remove impurities such as sand, gravel, metal, etc.

IV. XDLC IV type is installed vertically with a small footprint, equivalent to one-third of the horizontal installation. It is easy to maintain and the equipment's sand removal not only relies on centrifugal force, but also utilizes the self weight of sand particles to remove coarse impurities. The rotor can also operate in both directions, which is beneficial for improving sand removal efficiency and the service life of the rotor.

04

水力碎浆机 hydrapulper

水力碎浆机是造纸工业用来碎解浆板、废纸、废纸箱及抄损的设备。是槽内转盘叶片的机械作用和转盘旋转带动中浓搅笼的推进所引进的撕碎作用而达到破碎疏解的目的。

金属槽水力碎浆机由立式开口金属槽,带有叶片转盘支架,转子装带胶置传动,闸板阀等组成。

目前公司新开发的节能型碎浆机,在同样容积和同样动力前提下,产量可以提高一倍。

Hydrapulper is a device used in the paper industry to shred pulp boards, waste paper, waste paper boxes, and paper scraps. It is the mechanical action of the rotating disc blades in the groove and the shredding effect introduced by the rotation of the disc to drive the medium concentration mixing cage, which achieves the purpose of crushing and dispersing.

The metal tank hydraulic pulper consists of a vertical open metal tank, a blade turntable bracket, a rotor with adhesive transmission, a gate valve, etc.

At present, the company's newly developed energy-saving pulping machine can double the output under the same volume and power conditions.

●工作原理 working principle

The main function of the vertical low concentration hydrapulper is due to the mechanical action of the rotary blades and the hydraulic shear effect caused by the rotation of the rotor. When the rotor rotates, the slurry, paper material, and water flow are sucked in along the central axis and thrown out at high speed from the outer circumference of the rotor, forming a strong turbulent circulation. Due to the strong impact and tearing of the blades on the slurry, as well as the huge friction between different speed liquid layers, the slurry blocks and paper materials are strongly broken and dissociated in the liquid state. Unbroken paper sheets and fiber bundles are further dispersed between the rotor blades and the sieve plate. Good slurry that meets the requirements must flow out of the pulper through a certain specification of sieve holes.

●参数选型 model

目前碎浆机根据客户要求定制,最小可以做160升和0.5m³实验型设备,最大可以做到单机100m³,超过30立方碎浆机需要单独定制,可以致电公司电话0536-6081238,技术资料单独发给客户。

At present, the pulper can be customized according to customer requirements, with a minimum capacity of 160 liters and 0.5m ³ experimental equipment, and a maximum capacity of 100m ³ per machine. If the capacity exceeds 30 cubic meters, the pulper needs to be customized separately. You can call the company at 0536-6081238 and send technical information separately to the customer.

05

升流式压力筛

upflow pressure screen

●产品介绍 instruction

XRUV型升流式压力筛是我厂消化吸收进口样机技术研制开发出来的一种新型再生纸浆料筛选设备。该设备针对再生纸浆中杂质的特性设计为升流式结构,可广泛应用于各种废纸浆的粗筛、精筛及纸机前浆料的筛选,具有无可比拟的良好工作性能和可靠性,是各种国产压力筛用于再生浆处理的更新换代产品。

●工作原理 working principle

The UV type pressure screen adopts an upward flow structure design with bottom slurry inlet, bottom heavy slag discharge, and top light slag discharge, effectively solving the above problems. Light impurities and air in the slurry naturally rise to the top slag discharge outlet and are discharged, while heavy impurities can settle and be discharged from the bottom slag discharge outlet as soon as they enter the machine. In this way, on the one hand, it effectively shortens the residence time of impurities in the screening area, reduces the possibility of impurity circulation, and improves the screening efficiency; On the other hand, it prevents damage to the rotor and screen drum caused by heavy impurities, extending the service life of the equipment.

1、采用宽为0.15mm的精筛筛鼓,设置在粗筛之后,可有效去除浆中细小杂质及尺寸大于200um的油墨粒子,尤其值得注意的是对浆中胶粘物的去除率可达90%以上,是目前国内外推崇的代替各种热分散设备的最新设备技术方法(关于缝筛筛选法同热分散法解决胶粘物问题的比较详见华南理工大学制浆造纸工程国家重点实验室陈嘉翔教授撰写的刊登在《纸和造纸》2000年第三期“缝筛代替分散机在废纸系统的应用”一文)。

2、重杂质排入筛体底部的重杂质罐,防止转子与筛鼓磨损及损伤,减少停机时间。

3、轻杂质和空气从顶部尾浆口迅速排出。

4、筛选效率高,杂质在筛浆区停留时间短,显著降低杂质循环的可能性。

5、所需进浆压力低。

1. The fine screen drum with a width of 0.15mm, which is set after the coarse screen, can effectively remove the fine impurities in the pulp and ink particles with a size greater than 200um. It is particularly noteworthy that the removal rate of stickies in the pulp can reach more than 90%, which is the latest equipment and technology method to replace various thermal dispersion equipment at home and abroad at present. (For the comparison of the seam screen screening method and thermal dispersion method to solve the problem of stickies, see the article "Application of seam screen instead of disperser in the waste paper system" published in the third issue of Paper and Papermaking, 2000, by Professor Chen Jiaxiang, State Key Laboratory of Pulp and Paper Engineering, South China University of Technology for details.).

2. Heavy impurities are discharged into the heavy impurity tank at the bottom of the screen body to prevent wear and damage to the rotor and screen drum, and reduce downtime.

3. Light impurities and air are quickly expelled from the top tail slurry outlet.

4. High screening efficiency, short residence time of impurities in the screening slurry area, significantly reducing the possibility of impurity circulation.

5. The required slurry inlet pressure is low.

06

锥形磨浆机

conical refiner

●产品介绍 instruction

本机为卧式单方向进浆,径向上方出浆。主要由机座、电动机、机壳、转子、定子、进刀机构、减速机构等组成。该机采用整体机座,刚性好,动转平稳。该机主要用于造纸行业浆料粗、精磨及损纸、废纸再制浆,特别适合于棉浆、木浆、麻浆等长纤维浆料的打浆。

This machine is designed for horizontal unidirectional slurry feeding and radial upward slurry discharge. It mainly consists of a machine base, an electric motor, a casing, a rotor, a stator, a feed mechanism, a reduction mechanism, etc. The machine adopts an integral base, with good rigidity and smooth movement and rotation. This machine is mainly used for coarse and fine grinding of pulp in the papermaking industry, as well as for repurposing damaged paper and waste paper. It is particularly suitable for pulping long fiber pulp such as cotton pulp, wood pulp, and hemp pulp.

●设备优点 advantage

1、有较长的磨浆区、对纤维切断能力较强;

2、毛细纤维损伤较少,纤维的形态及匀整性好,磨浆后,抄成纸的裂断长、撕裂度、耐破度指标高;

3、低能耗、产量较高、效率较高、低噪音、易维修。

4、配置手动、电动操作装置。

1. Has a longer grinding zone and strong fiber cutting ability;

2. Capillary fiber damage is minimal, and the fiber morphology and uniformity are good. After grinding, the paper produced has high indicators of fracture length, tear resistance, and burst resistance;

3. Low energy consumption, high output, high efficiency, low noise, and easy maintenance.

纸浆设备自动控制系统

由旭日东研发生产的制浆设备效率高,能耗低,制浆效果好,操作简单,维护方便,可根据需求客户定制全自动控制系统,自动调浆、自动供浆,老板出差、在家可以通过手机、平板、电脑检测等远程智能操作。

The pulping equipment developed and produced by XuRiDong has high efficiency, low energy consumption, good pulping effect, simple operation and easy maintenance, and can be customized according to the needs of customers with automatic control system, automatic pulping, automatic pulp supply, the boss can travel at home through mobile phones, tablets, computers and other remote intelligent operation.

通过全自动控制系统来控制工厂内的供浆系统自动启停,以实现远程运维,旭日东也可为客户免费提供监管设备运行服务。

Through the automatic control system to control the automatic start and stop of the pulp supply system in the factory to achieve remote operation and maintenance, XuRiDong can also provide free supervision equipment operation services for customers.

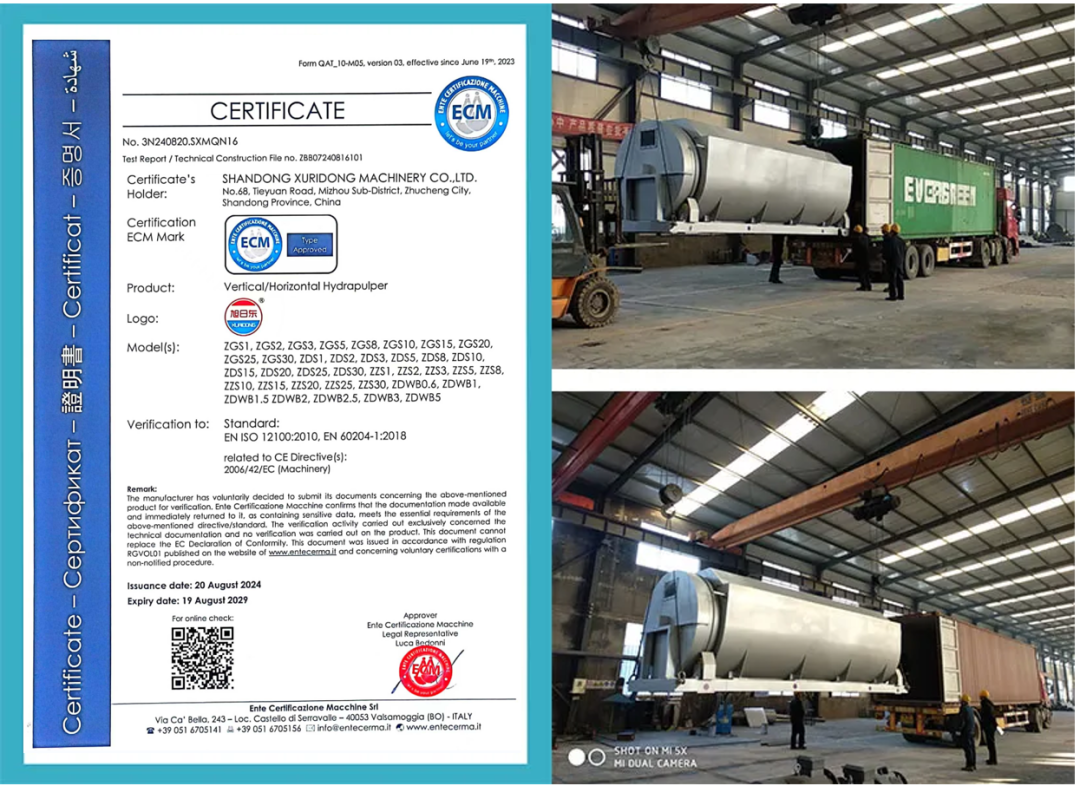

卓越品质获国际市场认可

旭日东于2008年公司获得了进出口权,频繁把设备出口到越南、泰国、印尼等东南亚国家, 2015年,旭日东在进一步巩固并扩大国内市场占有率的同时,不断拓展东南亚以外的国际市场,不断提升产品品质和完善售后服务。2019年由旭日东生产的微滤机系列产品顺利拿到了进入欧洲联盟市场的销售通行证——CE认证证书。

In 2008, XuRiDong obtained the import and export rights, and frequently exported equipment to Vietnam, Thailand, Indonesia and other Southeast Asian countries. In 2015, while further consolidating and expanding the domestic market share, XuRiDong continued to expand the international market outside Southeast Asia, and constantly improved product quality and after-sales service. In 2019, the microfilter series products produced by XRdong successfully obtained the sales pass to enter the European Union market - CE certification.

这一极具代表性的证书,被视为产品准入欧盟市场的通行证,标志着旭日东公司生产的微滤机系列污水处理设备在欧洲市场上得到了认可,符合公司国际化的发展目标。同年旭日东顺利与葡萄牙Sirplaste,DE MÓS PORTUGAL公司签定合同,每天处理9000吨的工业废水项目,又一次在欧洲市场上取得了客户的信任。

This highly representative certificate is regarded as the pass for products to enter the EU market, marking that the micro-filter series sewage treatment equipment produced by XuRiDong has been recognized in the European market, in line with the company's international development goals. In the same year, XuRiDong signed a contract with Sirplaste,DE MOS PORTUGAL to treat 9,000 tons of industrial wastewater per day, once again winning the trust of customers in the European market.

经过多年不懈努力和提升,旭日东公司产品不断出口美国、加拿大、西班牙、日本、欧洲、东南亚等20多个国家和地区,在国际市场上树立了良好的企业形象和品牌信誉。

After years of unremitting efforts and improvement, XuRiDong's products continue to export to the United States, Canada, Spain, Japan, Europe, Southeast Asia and other more than 20 countries and regions, in the international market to establish a good corporate image and brand reputation.

·欢迎旭日东参展·

如果您对旭日东感兴趣

即刻扫码报名参观

了解更多产品&技术

山东旭日东环保股份有限公司是一家生产制浆设备,承接环保工程的企业,专注于纸浆模塑制浆设备及污水处理设备的生产和研发。公司主要生产制浆设备、纸浆模塑设备、清洁制浆设备、环保设备和垃圾处理设备五大类,六十多个系列二百多种产品,有三十六种产品获得国家专利。

Shandong Xuridong Environmental Protection Co., Ltd. is an enterprise that produces pulp equipment and undertakes environmental protection projects, focusing on the production and research and development of pulp molding pulping equipment and sewage treatment equipment. The company mainly produces pulping equipment, pulp molding equipment, clean pulping equipment, environmental protection equipment and garbage disposal equipment in five categories, more than 60 series of more than 200 kinds of products, 36 kinds of products have obtained national patents.

公司坚持“科技兴业、管理增效”战略,以科技创新为动力,不断研发节能高效的新产品,以高新技术服务于客户,以优越的产品质量赢得客户的信赖。旭日东拥有自营进出口权,产品销往全国各地以及美国、欧洲、东南亚、中东、非洲等诸多国家和地区,在国际市场上树立了良好的企业形象。

The company adheres to the strategy of "science and technology development, management efficiency", takes scientific and technological innovation as the driving force, constantly develops energy-saving and efficient new products, serves customers with high and new technology, and wins the trust of customers with superior product quality. Xuridong has the right to import and export, the products are sold all over the country and the United States, Europe, Southeast Asia, the Middle East, Africa and many other countries and regions, in the international market to establish a good corporate image.

扫码参展 锁定黄金展位

产业之源·湾区之翼·世界市场

邀您商贸对接赢未来