零售循环经济解决方案

Ashley Spencer.

As consumers become more environmentally conscious, industries are coming under pressure, and none more so than food retailers; the top 10 supermarket chains account for a whopping 900,000 tonnes of plastic every year*, and unsurprisingly both consumers and governments are demanding more. Supermarket brands, including Woolworths, Waitrose, Iceland and Co-Op are all taking measures to minimise their impact, from refill stations to plastic-free aisles and sustainable plastic-free packaging solutions to safely store fresh produce, salads, and bakery goods.

Retailers Going Green

Our retail partners understand the value of innovative and sustainable solutions, they know that consumers won’t turn a blind eye to the plastic pollution fresh produce consumption is causing - rightly so, with 62% of produce ending up in households, they are all too aware of the volume of single-use-waste.

At Biopak we make it easy for our partners to adopt sustainable, carbon neutral, and compostable solutions, through innovation and collaboration. By working with Woolworths and Aldi, we are not only diverting waste from landfill, but ultimately minimising plastic from ever entering our eco-system.

Our collaboration with supermarket Woolworths and produce packer Hydro Produce created an industry-first: home compostable produce trays. An innovative first of many, with the introduction of custom-moulded tomato punnets for Kapiris Bros, and the world’s first compostable oyster tray, made from sugarcane pulp, in collaboration with Blue Harvest.

It is inspiring to see retailers taking decisive action to promote alternatives to fossil-fuel-based plastics, and together with consumer expectations and government-imposed legislation, we will ensure a better future for generations to enjoy. Recent global plastic bans across the likes of cutlery and straws have seen BioPak customer, Greencore, seek solutions for retailers looking for a more sustainable cutlery offering across their to-go section. These sustainably sourced FSC™ cutlery alternatives alone mean Greencore are diverting 58,248 KG of plastic from landfill and offsetting 302,928 kgCO2e every year.

Producers Going Green

Producers have an opportunity to support both consumers and retailers achieve their individual ambitions and wider CSR strategies, by choosing sustainable, certified home compostable packaging. Our partnership with Woolworth’s spurred the introduction of many firsts, but their commitment to lowering their CO2 footprint and environmental impact is what paved the way for all their produce partners to take the necessary steps during the production of some of our supermarket favourites.

Off-the-shelf ready solutions are a quick-win for producers like Westerway, a family run berry producer looking to lower their impact on the environment with our BioCane range. Whilst these solutions are quick, sustainable and easy, our experienced in-house industrial design team understand the need for more bespoke solutions when it comes to ensuring produce maintains its fresh look during transport. Our partnership with Costa Group, Kapiris Bros and Blue Harvest have seen solutions born from collaboration that achieves both desired environmental and performance goals.

Whilst retail-purchased produce maintains its position as the primary source of fresh vegetable and fruit, consumers who feel retailers aren’t moving quick enough, are taking things into their own hands. With consumers turning to e-commerce, why shouldn’t producers benefit from this shift in consumer behaviour?

Cue SunFresh Produce, an online direct-to-consumer producer. Their PiktFresh concept is the first UK Plastic Free Trust Mark awarded produce box, putting the BioPak sugarcane range to excellent use.

How Can Retailers & Producers Go Green?

Retailers have a huge opportunity to leverage customer demand for more sustainable solutions. By engaging with their network of producers, challenging convention, and championing innovation, they are able to have a huge influence on consumer behaviour, and impact on our environment.

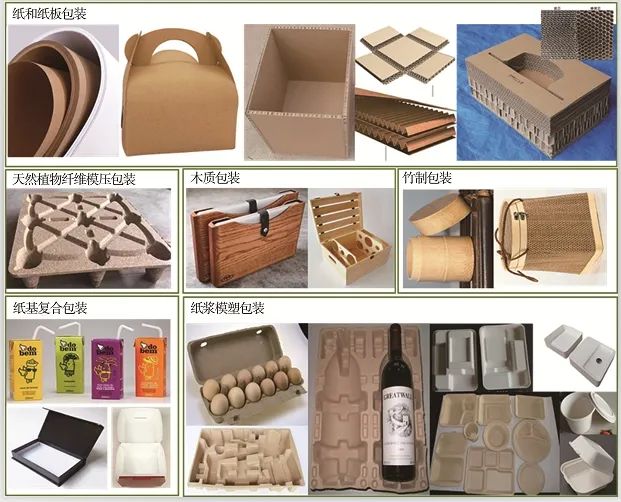

Retailers & Producers looking for sustainable, shelf-ready packs to substitute conventional plastic items are choosing BioPak retail packs and produce trays - made from rapidly renewable sugarcane pulp. Materials that are made from sustainably sourced and rapidly renewable materials like sugarcane, FSC™ certified wood or BioPlastic and are certified either home or industrially compostable, ensure we eliminate fossil-based resources and reduce our waste to landfill. These materials can reduce your carbon footprint and the certification supports the growth of the local composting infrastructure, creating jobs and enhancing soil.

Another way to significantly reduce your impact on the planet is to look out for carbon neutral products. An increasing number of brands, like BioPak, are taking responsibility for the unavoidable greenhouse gas emissions created through the production, transportation and disposal of their products, by actively reducing their carbon footprint and purchasing carbon credits to offset the remaining CO2.

Sugarcane packaging is functional, elegant and mouldable. Our industrial designer will work with you to create bespoke designs that suit your specification needs, whether it’s fresh produce or bakery goods. Our experienced team have worked with leading producers and retailers to create plastic-free solutions that don’t compromise on performance, ensuring your product is protected from production and transit to shelf. Find out more about our bespoke solutions in our Innovation By Design article.

BioPak’s BioCane trays are made from sugarcane pulp, also known as bagasse. Sugarcane pulp is derived from sugarcane, it is a by-product of sugar manufacturing, so we are using a waste product and making something new and sustainable from it.

The sugarcane pulp is pressed under high pressure with steam so it gets a very tight surface making it moisture repellent and it can be used in both chill and ambient environments, it can be frozen, oven-heated, and microwaved. The tray can take shrink wrap and flow wrap and it can also be heat-sealed which means using much less plastic for sealing.

2021.12.22-24

上海新国际博览中心

包装部落+美狮传媒集团强强联手,倾力为行业发声,开拓无限应用商机,联合创办2021上海国际植物纤维模塑产业展,致力于成为赋能植物纤维模塑全产业链的国际专业展会。在全球禁塑的大背景下,为植物纤维模塑行业构建平台,展示禁塑替代革新方案,彰显无穷环保潜力。与此同时,IPFM Shanghai 2021为植物纤维模塑行业打造各行业应用场景,开拓全域买家商机,涉及餐饮外卖、电子家电、日化美妆、奢侈品、生鲜果蔬、农产品、工业品、医疗卫生、电商快递物流、建材家居、园艺宠物、文创玩具等。

邮箱:dongzhengmao@126.com

邮箱:davidgao@msuccessgroup.com

邮箱:cloudzhou@msuccessgroup.com