| 本文来源:包装部落2018

PulPac PU300 - The world’s first standardized Dry Molded Fiber Production Unit

PulPac PU300 - 世界上第一个标准化干法模压纤维生产装置

Following the accelerating progress of the Dry Molded Fiber technology and great interest from the industry, PulPac together with its partners now reveals a standardized production line – the PulPac Production Unit 300 ton (PU300). Shifting from plastic converting or traditional fiber molding to Dry Molded Fiber is easier than ever, and even more attractive for the converters and brands that want to be leaders in the race for sustainable packaging.

随着干法模压纤维技术的加速进步,已经引起业界极大兴趣,PulPac 与其合作伙伴现在展示了一条标准化生产线——PulPac 300 吨生产单元 (PU300)。这个产线让我们从塑料加工或传统纤维成型,转向干法模压成型纤维,比以往任何时候都更容易,对于希望成为可持续包装竞赛中的领导者,这些加工商和品牌来说更具吸引力。

Turnkey providers and components via PulPac's partners

Interested parties are invited to sign up their interest in the PulPac PU300 and Dry Molded Fiber via an expression of interest form and request a sample package. Link above and here

www.pulpac.com/drymoldedfiber/machinery/

通过 PulPac 合作伙伴提供钥匙供应商和组件

邀请感兴趣的各方通过一份意向表签署他们对 PulPac PU300 和干模塑纤维的兴趣,并索取样品包。请点击以下的链接

www.pulpac.com/drymoldedfiber/machinery/

Designing concepts to distribute technology

The PulPac PU300 is engineered as a modular industrial production line, ready for food grade production of high volume and affordable Dry Molded Fiber products. The very first demonstration line has been set up in PulPac’s Tech Center in Sweden, where industrial food grade manufacturing of sustainable spoons made of pure cellulose fibers has begun.Fiber cutlery ready for production

设计概念以分配技术

PulPac PU300 设计为模块化工业生产线,可用于食品级大批量和经济型干模压纤维产品的生产。第一条示范生产线已在瑞典 PulPac 的技术中心建立,在那里开始了由纯纤维素纤维制成的可持续勺子的工业食品级制造。

The versatility, cost structure and market readiness of Dry Molded Fiber opens exciting opportunities for both fiber and plastic converters. In a few years, it will be possible to manufacture Dry Molded Fiber bottles and other complex products. But already today you can commercialize affordable high-volume products like spoons, trays, lids, bowls, – paper products that can hold grease and water without toxic chemicals – which are all ready for production with the PulPac PU300 platform. Single-use cutlery is a very interesting segment with billions of units demanded each year, and especially given the EU-wide ban on non-sustainable plastic cutlery coming to effect July 1st this year.

准备生产的纤维餐具

干模塑纤维的多功能性、成本结构和市场就绪性为纤维和塑料加工商带来了激动人心的机会。几年后,将有可能制造干模压纤维瓶和其他复杂产品。但是今天,您可以将价格实惠的大批量产品商业化,例如勺子、托盘、盖子、碗——可以容纳油脂和水而不含有毒化学物质的纸制品——这些产品都可以通过 PulPac PU300 平台进行生产。一次性餐具是一个非常有趣的细分市场,每年需求量达数十亿件,尤其是考虑到欧盟范围内的非可持续塑料餐具禁令将于今年 7 月 1 日生效。

Fast, effective and sustainable production

The dry process enables the PulPac PU300 to run extremely fast. Cycle time and production rates is on par with plastic manufacturing, and up to ten times faster than conventional fiber molding. Furthermore, Dry Molding does not waste valuable water resources nor impact the wastewater infrastructure. The process is much more energy-efficient than conventional fiber molding and enables material efficiency of up to 99% with in-line recycling. In summary, these process advantages yield up to 90% lower CO2 emissions at similar unit costs as plastic.

快速、有效和可持续的生产

干式工艺使 PulPac PU300 运行速度极快。周期时间和生产率与塑料制造相当,比传统纤维成型快十倍。此外,干成型不会浪费宝贵的水资源,也不会影响废水基础设施。该工艺比传统的纤维成型工艺更节能,并且通过在线回收使材料效率高达 99%。总之,这些工艺优势可在与塑料类似的单位成本下将二氧化碳排放量降低 90%。

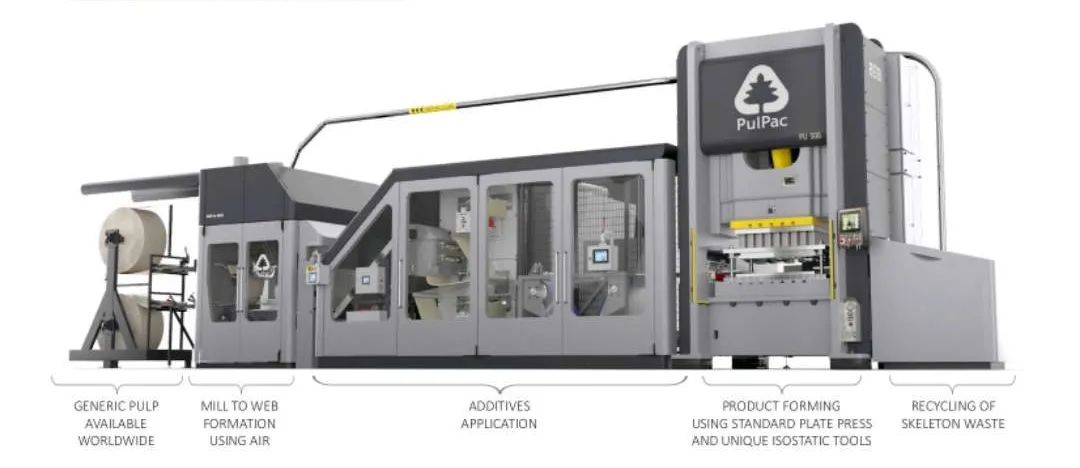

How it works

The PulPac PU300 is based on well-proven technologies and systems. The material used for production is regular pulp, cellulose fiber, a commodity item that is globally available.

这个怎么运作

PulPac PU300 基于久经考验的技术和系统。用于生产的材料是普通纸浆、纤维素纤维,这是一种全球通用的商品。

Within the PulPac PU300, a mill breaks up the pulp into separate fibers. These fibers are airlaid to a vacuum belt, forming a fluffy fiber web that is coated with non-toxic barrier additives and laminated with tissue. Thereafter, an electric servo press with a 300 tons force, customized for food grade production, molds the products with 0,2 seconds holding time enabling a production cycle of 3,5 seconds. All non-used material is re-circulated, giving close to complete material efficiency.

在 PulPac PU300 中,工厂将纸浆分解成单独的纤维。这些纤维被气流成网到真空带上,形成蓬松的纤维网,上面涂有无毒的阻隔添加剂,并与薄纸层压。此后,一台 300 吨力的电动伺服压力机,为食品级生产定制,以 0.2 秒的保压时间成型产品,使生产周期为 3.5 秒。所有未使用的材料都会重新循环,从而接近完全的材料效率。

设计可持续包装不单只是使用环保或回收材料而已,还须具备能让使用者立即停下来思考的创意美学。在消费者选购产品的过程中,商品包装必须在几秒钟内赢得其青睐并引发省思,因此整体包装得让消费者一眼就觉得它美观、安全且对环境友善。若设计师能成功将这些讯息整合到包装设计中,商品自然会在竞争激烈的超市卖场与电商中脱颖而出。

2021.12.22-24 · 上海新国际博览中心

包装部落+美狮传媒集团强强联手,倾力为行业发声,开拓无限应用商机,联合创办2021上海国际植物纤维模塑产业展,致力于成为赋能植物纤维模塑全产业链的国际专业展会。在全球禁塑的大背景下,为植物纤维模塑行业构建平台,展示禁塑替代革新方案,彰显无穷环保潜力。与此同时,IPFM Shanghai 2021为植物纤维模塑行业打造各行业应用场景,开拓全域买家商机,涉及餐饮外卖、电子家电、日化美妆、奢侈品、生鲜果蔬、农产品、工业品、医疗卫生、电商快递物流、建材家居、园艺宠物、文创玩具等。

邮箱:dongzhengmao@126.com

邮箱:davidgao@msuccessgroup.com

邮箱:cloudzhou@msuccessgroup.com