Zerobox

HUIDU ENVIRONMENTAL Booth No.: 4A15

• Adhesive tape-free: patented latch design, molding and sealing without needing either glue or adhesive tape.

• Environment-friendly: 100% recyclable, without generating any waste gas or waste-water during recycling; pure, non-toxic, tasteless, resistant to corrosion, acids and alkalis, directly available for packaging food.

• Convenient: low density (only 0.89-0.91), one of the lightest varieties of plastics; brand-new disruptive design, characterized by three-second molding, immediate use, and convenient operation.

• Three-proof performance: high heat resistance, continuous service temperature able to reach 110-120℃; water-proof material, fine surface rigidity and toughness, and high resistance to scratching and cracking; disposal latch seal, regarded as unpacked after seal failure.

• Inexpensive: good reuse effect and lower failure rate, use cost reduced by above 30% on the basis of traditional cartons.

Zipper adhesive 7.0

HAPPY PACK Booth No.: 4A38

Designed according to a unique formula, Zipper adhesive 7.0 has a viscosity higher than international standard; its initial adhesion and durability can meet transport requirements, and have passed measurement verification. Openable from either side and without tools, it can enhance user experience, improve enterprise image, and promote the classified recycling of paper and glue after opening (no twining of adhesive tape).

Four-wire express bags with excellent properties

Exxon Mobil

• Reduced material consumption: reduced packaging thickness and better performance in comparison to five-wire express bags; huge cost saving space for enterprises.

• Extreme toughness: excellent performance in terms of tensile strength/impact resistance/puncture resistance, guaranteeing the integrity of express packaging during logistics transport.

• Easily processing: solutions applicable to multiple film blowing equipment, characterized by sound extrusion performance and bubble stability.

• Matte surface: same appearance effect as common congeneric products on the market.

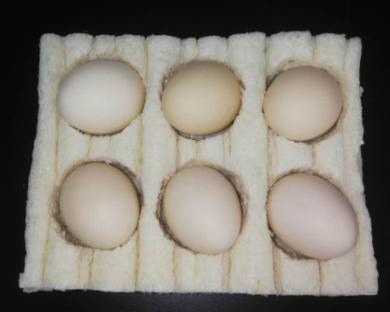

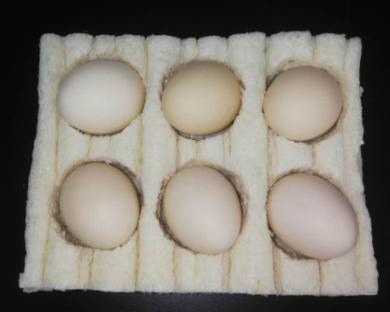

Bio-based polystyrene foam

Tianyi Booth No.: 4B23

Bio-based polystyrene foam adopts organic starch as raw material, and is non-toxic; as flexible foam, it is characterized by silkworm cocoon-like appearance, soft hand feeling, uniform size, and good buffer performance, and can be applied on cosmetics, sophisticated electronics, equipment & instruments, hardware, light-fixtures, artworks, household supplies, food cushion packages, window dressing, and other small-piece or large-volume and low-density products. It is also energy-saving, environment-friendly, beautiful, and fashionable. As packaging fillers, bio-based polystyrene foam is very popular in Japan, America, Australia, Europe, and many other countries. It can not only protect products and environment, but also upgrade product level and customer experience.

Backing paper-free heat-sensitive paper

Antac Label Booth No.: 4A01

• Backing-paper free, green and environment-friendly;

• High-performance release coating, stable release force, and unaffected printing effect;

• Same label number, smaller weight, and smaller volume.

Plastic recycling packaging box

Huili Booth No.: 4A52

The plastic recycling packaging box of “Huili” adopts domestic-advanced plastic cellular board extrusion technique, edge-banding technique and abutting molding technique, and is characterized by enhanced basic packaging functions and box durability. The novel cellular boards have a higher resistance to compression, puncture, and tearing, and can achieve different protection effects based on customized material strength and specifications. Recyclable for as many as 50 times, it answers the call of the society for environmental protection, and offers new environment-friendly and recyclable packaging options for the commodity circulation field.

Bio-based degradable film bags

Hanfeng New Material Booth No.: 4B03

• High additive amount of starch (as high as 40%), and high temperature resistance (-20℃-80℃);

• Feedback free, reliable quality, environment-friendly ink, and safe and green design.

AnteoTM (Borstar BBT technology)

Borouge Booth No.: 4A29

• Unparalleled processing performance: convenient processing even under a much lower extrusion pressure (at 15% lower than that of traditional metallocene LLDPE), plus lower energy consumption;

• Heat-sealing integrity and heat-sealing speed: Heat-sealing materials applied to composite and non-composite packaging films can realize high-speed packaging, thus guaranteeing lower energy consumption and less material waste;

• Phased breakthroughs in puncture resistance: significantly reduced deterioration or damage risks for articles;

• Good optical performance, able to improve shelf display effect.

PLA extrusion foaming

GreenF Booth No.: 4B142

• Low-carbon green materials, safe, environment-friendly, able to realize home composting;

• Low cost of materials (basically equal to the cost of traditional materials), and simple foaming process, without requiring blowing promoter;

• Pioneering all-starch material in China;

• Sustainable material, derived from plants and unrestrained by petroleum status.

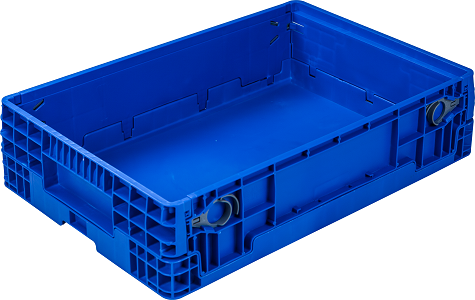

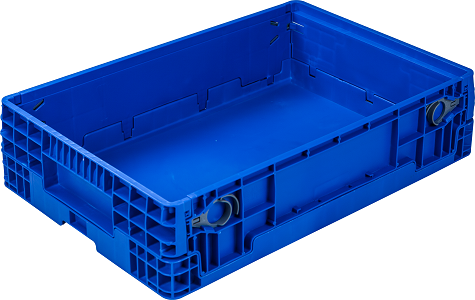

Folding box

Ningbo Joy Booth No.: 4C65

• Stacking design available in both assembling and folding;

• Reduced volume after folding (1/5-1/3 of original volume), and significantly reduced cost in logistics circulation and warehousing;

• Assembled with different components, and low repair cost (only necessary to replace damaged components).

沪公网安备 31010702006282号

沪公网安备 31010702006282号